- Out of stock

BLOG - recent posts

Lots of cutting of a very thin sheet

CNC carbon sheet engraving

Material thickness 2mm, repeatability 100%

CNC cutting of logo on a carbon fiber sheet

Pockets depth 0.3mm

Made of 4mm cf sheet

Openwork type parts made of 4mm carbon sheet

small carbon fiber parts 3 and 4mm thick

Large and thin 4mm carbon fiber parts

Custom made multirotor tubes

Security Policy

Security Policy

Your connection to our store is secure - we use SSL encryption.

Shipping rules

Shipping rules

Products are shipped immediately after receipt of payment confirmation.

Return rules

Return rules

You have 14 days for return if the product is unused.

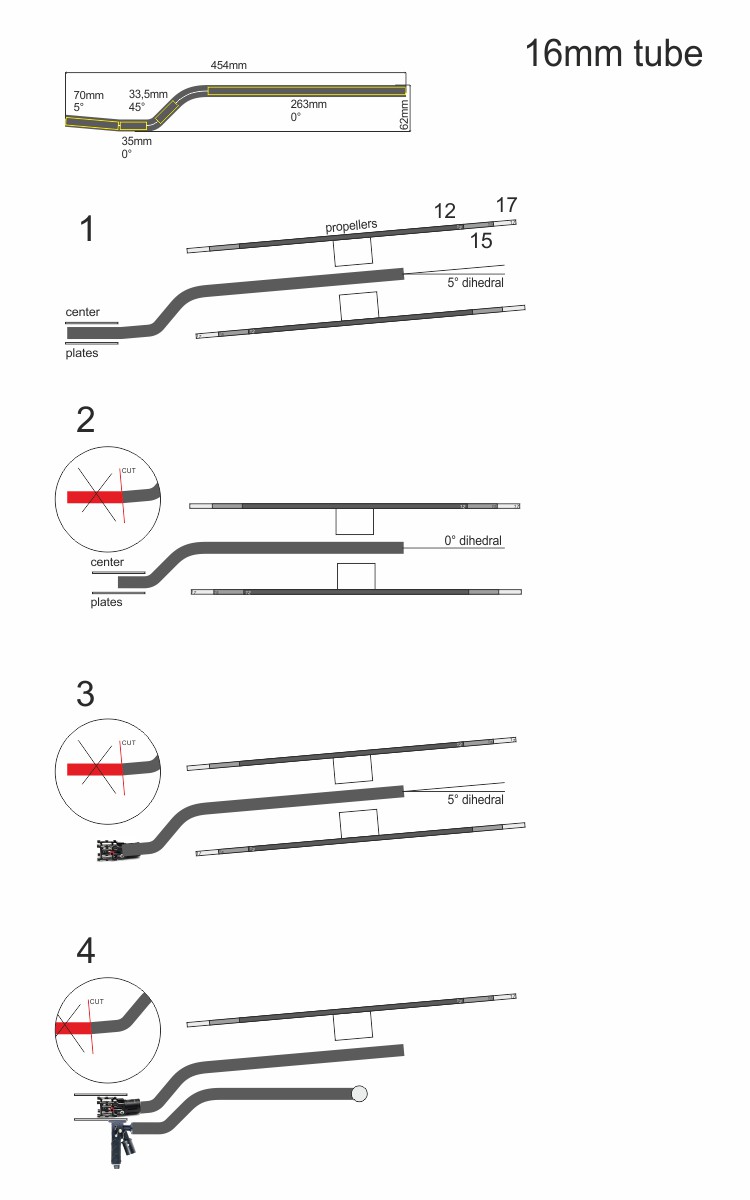

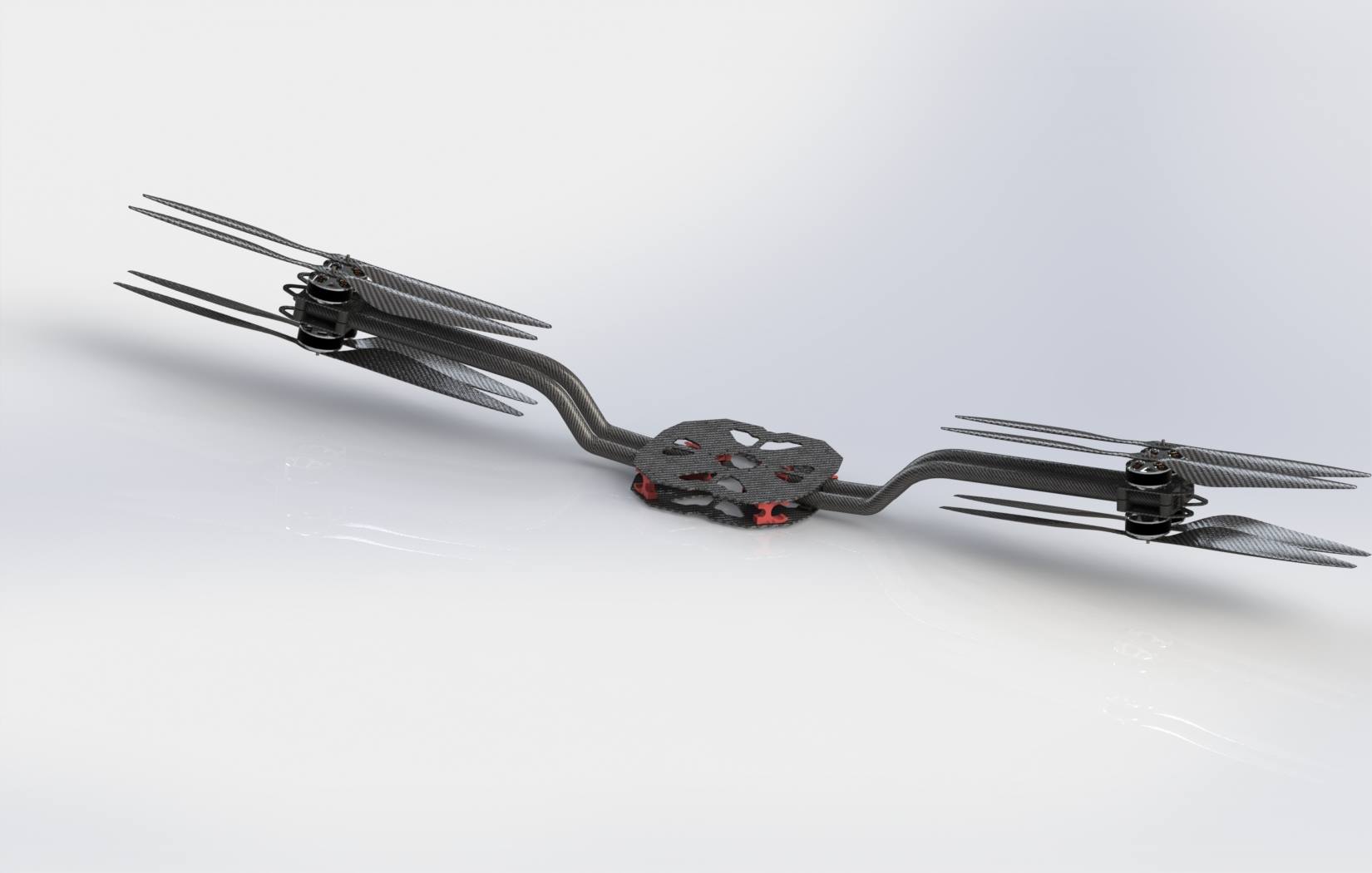

These custom multirotor tubes have been made to provide you an arm replacement solution for nearly any multirotor. They are section shaped and each part may be used for a particular purpose. The first section is 5 degrees angled to the tube motor section giving a 5 degrees dihedral - this section is intended to be used in simple horizontal clamps. The second section is intended to be used in any foldable mechanism, in such case these mechanisms already have dihedral built in, or with standard clamps with no dihedral.

The shape of the tubes rises the motor lowering the gravity center of the entire multirotor and allows easy mounting of bottom motors in coaxial construction with piece of mind that the bottom motor would hit retractable legs. Both the low gravity center and the dihedral mechanically stabilize multirotor the tubes are on.

Here are the main advantages of the bent tubes:

- low gravity center of a multirotor

- 5 degrees dihedral

- easy coaxial constructions

Number 1 on the above photo shows the actual product.

The following drawing shows exactly the shape and the size of the tube.

On drawing 4 the tube is also used for multirotor retractable legs.

Data sheet

No customer reviews for the moment.

Custom made multirotor tubes. Reinforced version with wall 1,5mm thick.

Custom made tubes for multirotor arms or multirotor legs. 9.5 degrees angle.

Custom made multirotor tubes